Safeguarding Silos: Essential Steps for Fumigation, Ventilation, and Sealing.

Fumigations are carried out to kill Stored Products Insects damaging food grains. More than 18 species of stored products insects in India but only few Species are causing maximum damages. Primary Insects damages the grain from inside the grain while Secondary Insects feeds on damaged grains Damages percentage can start from 10 to 30 %. If Fumigations services in pune treatment were not carried out leading to huge losses.

FumigationsTreatment carried out in air tight enclosure for a particular exposure period with gaseous chemicals which kills insects and other pest.

Scientific Method :

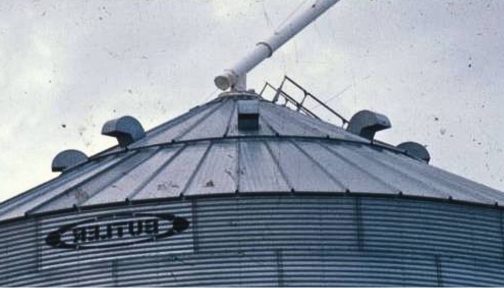

silo fumigations services in pune with Phosphine Generator which releases phosphine gas quickly after reaction between fumigant and water directly under controlled mechanism and circulation of gaseous fumigant across the silo.

Conventional Method :

Fumigation by application of fumigant directly to commodities, which reacts with moisture inside the enclosure and fumigant are circulated with help of J-system

Silo Ventilations:

Steel are Good Conductor of Heat. During summer outer layer of commodities became hot while inner layer stay cool. During winter outer layer of commodities became cool while inner layer stay warm. Grains are living organisms and release water vapor during respirations. Difference in temperature gradient results in condensation of moisture at top during winter and at bottom portion during summer. Moisture condensation can damages commodities, even germinations at top layers.

Silo Sealing:

Permanent Sealing – Silo Walls Joints, Roof top joints, sprout sealing.

Temporary Sealing – Vents, manhole, opening duct, aeration pipes. Inputs & discharge points.

Silo must be properly sealed from all sides for effective fumigation. This includes sealing all entry and exit points to prevent gas leakage, as well as testing the air quality inside the silo to ensure that it is safe for fumigation services. Once the silo is properly sealed, the fumigant gas is released into the silo using a equipment.

For effective fumigations Silos have to be air tight to prevent leakages of fumigants. Most of silo’s are water tight but air tightness are not done and checked properly. Leaked silos also lead to development of resistant species of insects. Risk of fire hazards is increase in leaked silos'.

Critical Success factors

-

Proper sealing of silos structures and vents, input, discharge points etc.

-

Clean grains, Too much dust prevent diffusion of fumigant preventing equal distributions across the silo.

-

Moisture content of grains (not less than 9%) and space within silos ( not less than 50% RH).

-

Temperature less than 11 degree Celsius results in improper diffusions.

-

Fumigant concentrations of minimum 200 ppm for 7 days.

Sealing materials

Roof Vent sealing

Sealing of silo at top conical structure at Roof & wall Joints

Conclusion:

Effective fumigation is not just a pest control measure—it's a critical part of safeguarding food security and ensuring the longevity of stored commodities like grains. With over 18 species of stored product insects present in India, timely and scientifically executed fumigation is essential to prevent damage ranging from 10% to 30%. Whether through advanced silo fumigation systems or conventional methods, success depends on airtight sealing, proper temperature and humidity, and accurate fumigant concentration levels.

Neglecting these critical factors can lead to not only economic loss but also resistance development in pests and safety hazards. If you're looking for reliable and scientifically backed pest control solutions, explore our services tailored to local needs through Pest Controls Near Me in Pune.