"Integrated Pest Management (IPM) at Food Factories"

Integrated Pest Management (IPM) is essential for every food manufacturing facility to ensure the safety, quality, and compliance of food products. By implementing IPM, food factories can protect their products from contamination, maintain hygiene, and uphold standards like Hazard Analysis and Critical Control Points (HACCP), American Institute of Baking (AIB) International Consolidated Standards of Inpseciton – Pre requisite programs and the British Retail Consortium (BRC) Global Standards – Food Safety. IPM also plays a crucial role in effective pest control in Pune and pest control services in Hyderabad, helping food manufacturers prevent infestations such as cockroach control in Pune and ensuring a clean, pest-free production environment.

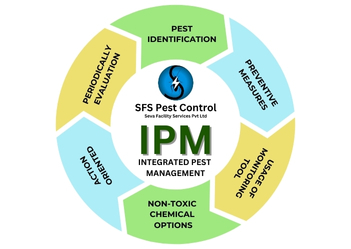

What is Integrated Pest Management (IPM)?

IPM is a systematic, science-based approach to controlling pests in an environmentally sustainable, cost-effective, and efficient manner. It integrates multiple strategies to prevent, monitor, and manage pest populations while minimizing impacts on human health, the environment, and non-target organisms.

Key Aspects of IPM

-

Control Measures

IPM utilizes three primary control methods:

- Physical Controls: Barriers, traps, and temperature changes (either extreme cold or extreme heat) treatments to eliminate pests by which they cannot survive.

- Chemical Controls: Application of repellents, pesticides, and fumigation, ensuring compliance with food safety regulations.

- Biological Controls: Introducing natural predators or bio-control agents where feasible.

-

Monitoring and Identification

Early detection and regular inspections are critical to effective pest management.

- Inspection Routines: Scheduled checks in high-risk areas like storage rooms, production lines, and loading docks.

- Monitoring Devices: Utilizing pheromone traps,insect light traps, glue traps, and other pest monitoring devices placed strategically to track pest activity.

- Pest Identification: Analyzing pest behavior, breeding grounds, and pest entry points for targeted action and sealing vulnerable spots that are allowing pest movement.

-

Documentation and Compliance

Maintaining proper records ensures traceability and helps during audits.

- Detailed Logs: Document pest occurrences, actions taken to pest occurrences, and future plans to prevent pest recurrence (corrective action).

- Regulatory Compliance: Adhering to food safety standards reduces contamination risks due to pests and ensures compliance to national and international food safety standards.

-

Prevention Strategies

Prevention is the most effective way to maintain a pest-free environment.

- Facility Design: Seal pest entry points, install air curtains and screens, and ensure doors and windows are pest-proof.

- Sanitation: Schedule regular cleaning to eliminate food residues and debris that attract pests.

- Storage Practices: Use pest-resistant packaging and store materials off the ground and away from walls.

Importance of IPM in Food Factories

- Cost-Effectiveness:Pest preventive measures reduce long-term costs of pest management and reduce pest risks.

- Environmental Sustainability:Minimize use of harmful chemicals and their impact on the environment.

- Enhanced Food Safety:IPM reduces the risk of contamination from pests and product recalls due to pest infestation in products.

- Regulatory Adherence: IPM improves the ability of a food factory to meet national and international food safety standards, safeguarding the facility’s reputation as a high quality manufacturer of safe food products.

Steps to Implement IPM

- Risk Assessment: Identify areas vulnerable to pest infestations and assess potential risks.

- Prepare an IPM Plan:Tailor the IPM plan to the facility's specific needs, addressing each pest type and unique aspects of the facility.

- Train Staff: Educate employees about pest prevention and the importance of prompt reporting.

- Partner with Professionals:Collaborate with licensed pest control experts for specialized services.

Common Pests Found in Food Factories

-

Rodents

Damage materials, machinery, packaging, and electrical components.

- Control Measures: Bait stations, traps, rodenticides, and rodent exclusion techniques.

-

Insects

Examples: Ants, flies, termites, bed bugs, spiders, and more.

- Control Measures: Insecticides, UV light traps, insect proof screens, physical barriers, elimination of cracks and crevices that could harbour insects and rigorous sanitation.

-

Stored Product Pests

Examples: Beetles, weevils, and moths.

- Control Measures: Heat treatments, pheromone traps, insect light traps, fumigation, repellents, and airtight storage.

-

Birds

Contaminate surfaces and damage raw materials.

- Control Measures: Netting, spikes, sound deterrents, and scarecrows.

Integrated Pest Management (IPM) is a comprehensive solution for maintaining a pest-free food manufacturing environment. By combining prevention, monitoring, and control measures, food factories can safeguard their products and reputation while promoting sustainability and regulatory compliance.

Wishing you a pest-free and safe environment,

Hiraman Rathod

Seva Facility Pest Control Services

Phone: 91 9112003300

Email: info@sevafacility.com